Bluetooth technology has come a long way from being just a file-sharing platform between two devices or playing music on the speaker, to being a modern-day connectivity solution. Today, Bluetooth is already one of the most common wireless standards used in IoT devices. Bluetooth is looking more lucrative than ever on the Industrial Internet of Things (IIoT) front, thanks to technological advancements (Bluetooth mesh networks), ultra-low power consumption, and growing awareness among enterprises about BLE communication technology. According to trends by the Bluetooth SIG’s recent 2021 market update, by 2025, annual Bluetooth-enabled device shipments will exceed 6 billion.

In this blog, we will deep dive to understand various Bluetooth topologies, BLE protocol stack, the emergence of Bluetooth mesh networking, Bluetooth technological advantages in the Industrial IoT, and emerging IIoT applications using Bluetooth and BLE mesh technology.

Bluetooth Topologies: Bluetooth technology supports different topology options that are :

- Point-to-Point: Pairing of two Bluetooth devices

- Example: Mobile phone and portable Bluetooth Speaker

- Broadcast: Establishing one-to-many (1:m) device communication

- Example: Playing music on a smartphone and simultaneously casting photos on different applications.

- Mesh: establishing many-to-many (m:m) device communications

- Example: Connecting a large number of BLE sensors to communicate with one another.

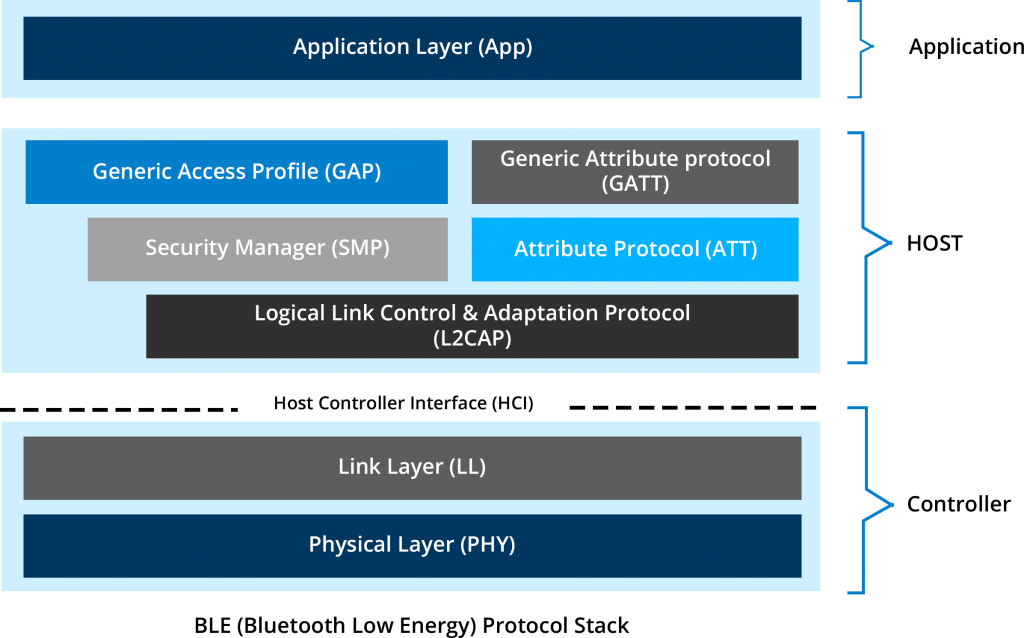

BLE Protocol stack: It can be said that the protocol stack is the heart of Bluetooth technology. The protocol stack specifies how the technology will work and how it will be used to accomplish the tasks. The below picture gives us a basic overview and functions of different layers of the BLE protocol stack.

- The Controller includes the following layers :

- Physical Layer (PHY): PHY is the bottom layer of the BLE stack and responsible for transmitting and receiving information over the air (OTA) via radio waves.

- Link Layer (LL): The Link layer is responsible for scanning, advertising, and creating/maintaining connections and directly interfaces to the physical layer (PHY).

- Host Controller Interface (HCI): It enables the communication between the controller and the host via the serial interface.

- The Host includes several layers :

- Logical Link Control and Adaptation Protocol (L2CAP): The L2CAP sits on the top of HCI layers and enables the data transfers between the upper layers of the host (GAP, GATT, application) and the lower layer BLE protocol stack.

- Attribute Protocol (ATT): It defines how data/attributes are represented in a BLE server database and also defines methods by which that data/attribute can be read or written.

- Security Manager (SMP): The SMP is used for security management and defines the process of key distribution and pairing along with access to the services such as device authentication, data integrity, and confidentiality.

- Generic Access Profile (GAP): GAP helps to determine how the BLE devices can or can not interact with each other and is responsible for connection functionality.

- Generic Attribute Profile (GATT): GATT defines the way two Bluetooth Low Energy (BLE) devices transfer data back stored by Attribute protocol (ATT).

- Application layer:

- Application (App): The application layer is the uppermost layer like any other type of system. It is responsible for the user interface, containing logic, and data handling for everything related to the actual use-case that the application implements.

The Emergence of Bluetooth Mesh Networking

Bluetooth mesh networking that was officially launched in 2017 was a much-anticipated addition to the Internet of things (IoT) connectivity space. A large-scale network can be created via BLE mesh where hundreds and thousands of devices can connect and communicate with one another reliably and securely. The benefit of Bluetooth mesh is its extended range, since the nodes can relay messages to far away nodes through intermediate nodes, a network’s range and device reach can be extended. Even if one node drops from the network, other nodes can participate and send the message to one another. The benefits of BLE mesh make it suitable to choose it over other wireless connectivity options. Today, BLE mesh is used widely in applications such as smart HVAC, building automation, condition monitoring, Industry 4.0, location services, etc.

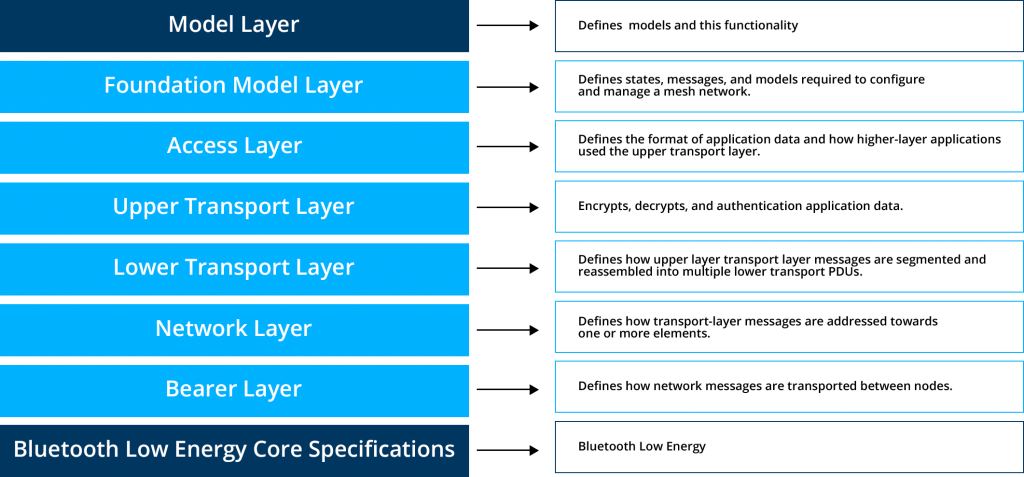

BLE mesh architecture: The Bluetooth mesh runs on the top of the Bluetooth Low Energy (BLE) stack. The below figure outlines the Bluetooth mesh stack and layers involved.

Image credit: Bluetooth SIG

What makes Bluetooth Ideal for Industrial IoT Applications?

- Connectivity: Many of us believe the maximum distance for Bluetooth connectivity is several meters at best, but in reality, Bluetooth can operate over greater distances and performs well in harsh conditions that typically exist in industrial environments. For instance, the latest standard – Bluetooth 5.0 can transmit messages even up to 1km.

- Number of devices: When it comes to Bluetooth mesh, there is almost no limit to the number of devices that can be connected and the amount of data to be transmitted between multiple nodes.

- Operation cost: With its ultra-low power consumption, Bluetooth can help maintain lower operation costs. For instance, a single Bluetooth device can run even up to 5 years on a small battery.

- Self-healing capabilities: Even if a node leaves the mesh network, the other nodes can still communicate with one another. This feature is available with BLE mesh technology and is very beneficial in industrial IoT applications for uninterrupted communication.

Emerging IIoT Applications using Bluetooth, BLE / BLE Mesh Technology

- Smart HVAC and Building Automation: Due to Bluetooth’s ultra-low energy consumption and easy installation, today Bluetooth mesh technology is widely used in smart HVAC and building automation solutions. Various sensors such as air quality, temperature, pressure sensors, etc can create a mesh to communicate with one another to trigger an action. The Bluetooth wireless mesh technology enables customers with easier installation and reduces maintenance and operational cost.

- BLE-based Asset Tracking: Using Bluetooth Low Energy (BLE) based tracking tags, assets can be tracked throughout the buildings, warehouses, and/or within defined Indoor/ Outdoor areas. For instance, BLE-based asset tracking can be used in the manufacturing industry to track the assets from production lines to the dispatch area resulting in improved operations.

- Smart Factory: A robust and reliable connection can be established using Bluetooth technology to transfer the data from the sensors or Industrial machinery to Bluetooth-based smartphones and tablets. These devices act as central control devices within factories for controlling, monitoring, and automation purposes.

VVDN Expertise in Bluetooth, BLE, and BLE Mesh Solutions

VVDN has vast experience in design, developing, and manufacturing end-to-end solutions using Bluetooth 5.0, BLE, and BLE mesh ranging from trackers, sensors, smart HVAC, and other Industrial IoT solutions. Our in-house engineers have hands-on experience working on the software and frameworks including Unity testing framework, Google test, Wireshark, Lightblue used for BLE monitoring, provisioning, and testing to achieve optimum results. A dedicated in-house RF lab is set up for the hardware testing of the BLE-based products. Feel free to contact us with your requirements in regard to Bluetooth/ BLE mesh solutions and professional advice.