Overview

In today’s digital age, laptops have become indispensable tools for work, study, and leisure. But have you ever wondered what goes into making these incredible machines?

Laptop manufacturing is a highly precise and sophisticated process involving the combination of engineering and designing processes to high-precision assembly and manufacturing to create a portable computing device. This process has several stages, from the initial concept and design to the assembly of components and rigorous testing.

Let’s take a behind-the-scenes look at the fascinating journey of laptop manufacturing.

Concept and Design

Designers and engineers brainstorm to develop a device that’s not only functional but also aesthetically pleasing and user-friendly. They consider factors such as size, weight, performance, and battery life. Prototypes are built and tested, leading to refinements in both hardware and software. Once that is done and laptop is ready for mass manufacturing the next stage comes.

Component Sourcing

Once the design is finalized, it’s time to gather the necessary components. A laptop is made up of numerous parts, including:

Central Processing Unit (CPU): The brain of the laptop, responsible for executing instructions. Intel is a major player in this space, providing processors that power many laptops.

Memory (RAM): Short-term storage that helps the laptop run applications smoothly.

Storage (SSD or HDD): Long-term storage for your files and applications.

Motherboard: The main circuit board that connects all the components.

Display Screen: The visual interface through which you interact with the laptop.

Keyboard and Touchpad: Input devices that allow you to control the laptop.

Battery: Provides power to the laptop when it’s not plugged in.

Each of these components is sourced from various suppliers around the world. Quality and compatibility are crucial, so manufacturers often work closely with their suppliers to ensure the best components are used.

Assembly

The assembly process is a detailed and precise operation, divided into two main stages: the panel kit and the bottom assembly.

Panel Kit Assembly:

Screen Preparation: A protective film is applied over the LCD (liquid crystal display) screen. The screen is then connected to the motherboard via a cable.

Frame Installation: The screen is set into a frame, which already includes the webcam, microphone, and antenna cover. The webcam and microphone are connected, and the Wi-Fi antenna is installed. Hinges are attached to connect this assembly to the rest of the laptop.

Final Touches: A cover is placed over the cables and antennas, and a thin metal frame is pressed around the screen to secure everything in place.

Bottom Assembly:

Connecting the Top and Bottom: The top cover, which includes the panel kit, is attached to the hinges, and the touchpad is integrated. The right and left speakers are installed into the top cover.

Motherboard Installation: The motherboard is mounted, followed by the attachment of high-powered fans to prevent overheating. Wi-Fi and Bluetooth modules are added, along with the SSD for data storage. The battery is then fitted to power the laptop’s components.

Keyboard Integration: The keyboard is secured into its designated opening on the top cover.

Final Markings: A laser etches the model, batch numbers, and manufacturer’s information onto the back of the laptop.

Final Markings: A laser etches the model, batch numbers, and manufacturer’s information onto the back of the laptop.

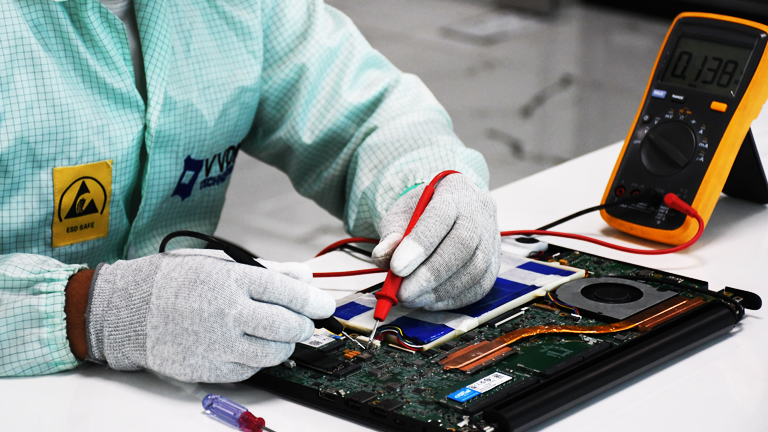

Quality Control

Once assembled, the laptop undergoes rigorous testing. Automated machines check the functionality of the screen, keyboard, and overall performance to ensure everything operates as expected.

Packaging and Distribution

After passing quality control, the laptop is carefully packed along with its accessories, such as the power adapter and user manuals. It is then shipped to retailers or directly to customers.

Software and Updates

The laptop comes with an operating system and pre-installed applications. Software updates are provided to enhance performance and security. Intel also updates drivers for their processors to maintain compatibility and efficiency.

Conclusion

From design to assembly, the journey of a laptop involves numerous intricate steps and collaboration between various experts. Companies like Intel play a vital role in equipping these devices with powerful processors, underscoring the technological advancements in laptop manufacturing.

VVDN’s Role in Laptop Manufacturing

VVDN, with extensive expertise in the engineering sector, has developed production-ready laptops based on the Intel® platform. These laptops feature the Intel® Celeron® processor and are available for white-labeling by OEMs. VVDN has handled all aspects of the laptop’s hardware, software, mechanical design, testing, and manufacturing entirely in-house.

Our seven dedicated manufacturing units support various aspects of laptop production, including PCB assembly, product assembly, tool and mold development, rapid prototyping, and comprehensive testing and validation.

For more information about VVDN’s laptops, please click here or contact us at info@vvdntech.in.